|

Category

|

Standard

|

Typical Grades

|

|

Structural & General Engineering

|

EN / ASTM

|

S235JR, S275JR, S355JR/J0/J2, A36, A283, A572 (Gr 42/50)

|

|

Mild Steel / Commercial Quality

|

EN / JIS / Chinese

|

Q195, Q215, Q235B, SS400, SPHC/SPHD/SPHE

|

|

High-Strength Low Alloy (HSLA)

|

EN

|

S315MC, S355MC, S420MC, S460MC, S500MC, S550MC, S600MC, S700MC

|

|

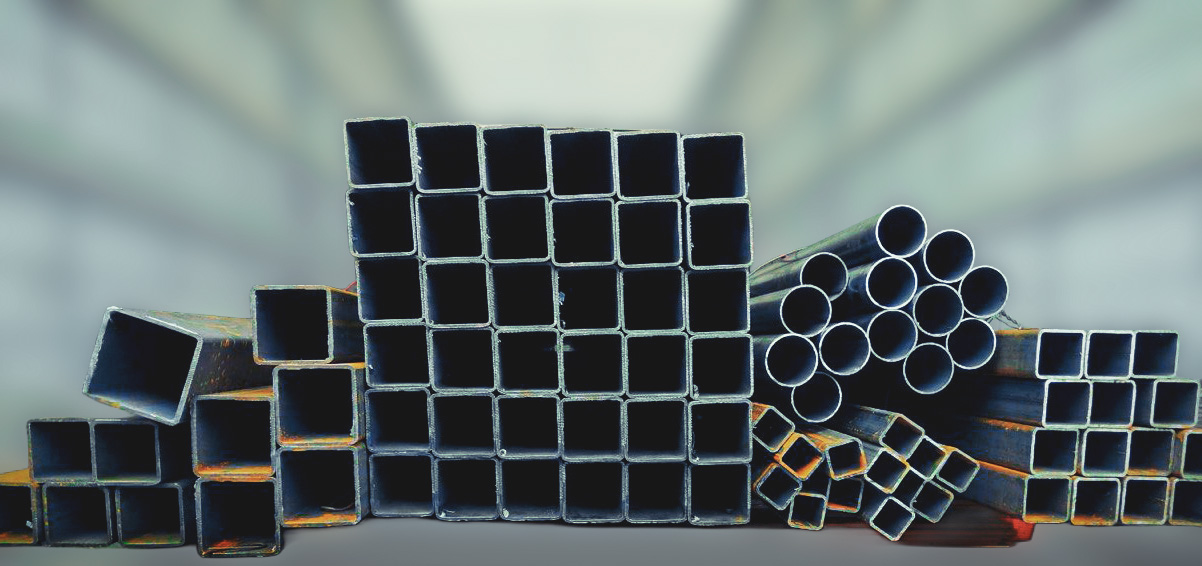

Pipe & Tube Grades

|

API / EN

|

API 5L A/B/X42/X52/X56/X60/X65, L245, L290, L360, L415, EN 10219 S235/S275/S355

|

|

Boiler & Pressure Vessel

|

EN / ASTM

|

P235GH, P265GH, A516 (55/60/65/70), A285, A299

|

|

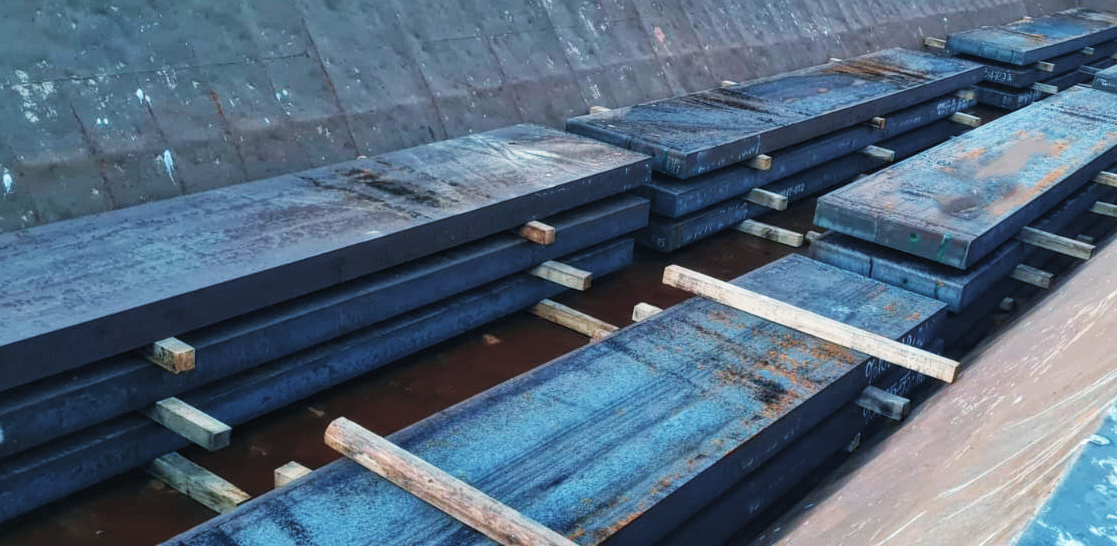

Shipbuilding

|

ASTM / EN

|

A, B, D, E, AH36, DH36, EH36

|

|

Wear Plate (Before QT Stage)

|

EN / Chinese

|

NM360, NM400, NM450, AR400, AR450, AR500

|

|

HRPO / Rerolling Feedstock

|

EN

|

CQ, DQ, CR Full Hard

|

|

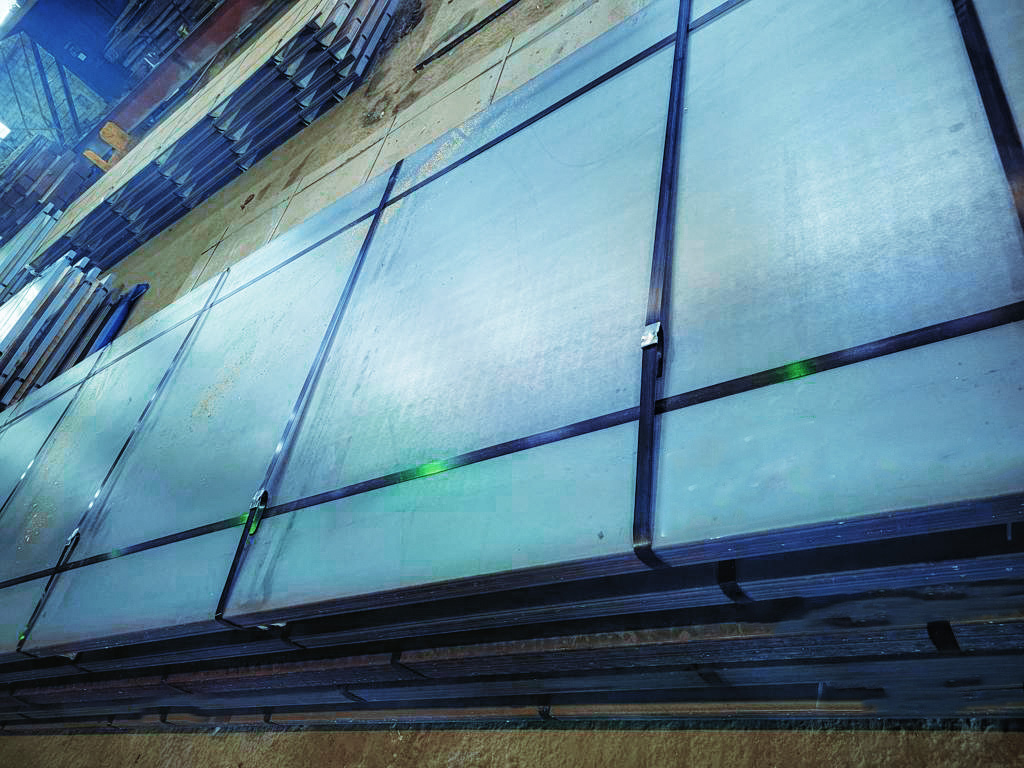

Carbon Structural Steel

|

GOST 380

|

St0, St1, St2, St3 (сп/пс/кп)

|

|

Hot-Rolled Sheets & Strips

|

GOST 19903

|

St0, St1, St2, St3, St4, St5

|

|

High-Strength Low-Alloy

|

GOST 19281

|

09G2S, 10G2S1, 14G2, 15HSND, 10HSND

|

|

Boiler & Pressure Vessel Steel

|

GOST 14637

|

16GS, 17G1S, 22K, 20YuCh

|

|

Weldable Structural Steel

|

GOST 27772

|

S245, S255, S275, S345, S390, S440

|

|

Welded Structure Steel

|

GOST 5520

|

09G2S, 10HSND

|

|

General HR Plate & Strip

|

GOST R 52544

|

St3, 09G2S, S235/S355 equivalents

|